Product configurator

The SEMI automatic mode enables the operator to actively intervene in the workflow and, if necessary, to initiate manual process steps. Complex sub-processes, on the other hand, can be carried out fully automatically using fixed movement sequences. Immediate as well as fluid and precise movements allow high cycle times while still under constant control of the operator.

The design of the handling device as well as the ergonomically arranged control elements enable the operation of the device in both automatic and manual mode.

Write us an email, give us a call - we will be happy to arrange a consultation appointment with you.

You are also welcome to download our brochure in advance.

The handling system can be operated either directly on the device or via a wireless hand-held device. With all the necessary functions and operating parameters on display, you are always in control.

As a system supplier, we can offer you a complete solution for your application, ranging from steel construction to on-site commissioning.

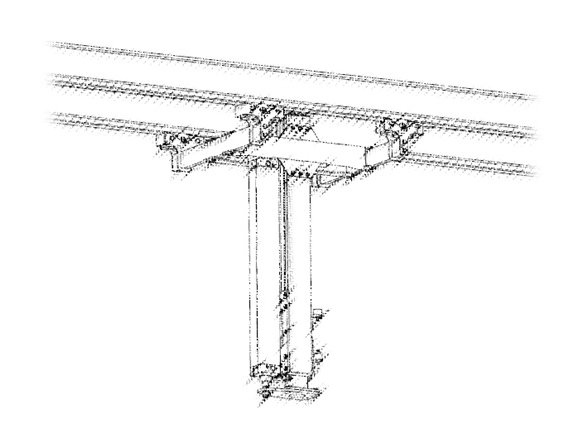

In order to cover work areas far beyond those of a classic industrial robot, standardized and well-tried components from crane technology are utilized.

Depending on the force and acceleration requirements frequency controlled or servo drives are used.

The data exchange with external programs allows for uncomplicated adaptation of the workflow, i.e. container positions can be approached automatically or gripper settings can be made without loss of time and with a high level of process reliability. Various data such as QR- or barcodes can also be read out and sent directly to other recipients for further processing.

An application-specific length measuring system ensures the position of the device in the work area is securely determined.

The vertical stroke can be realized electrically or – in case of very delicate applications – pneumatically.

Movements in all three axes are carried out by small and compact actuators.

The largely custom-made design of the gripper enables the operator to pick up the workpieces both manually or in human-robot collaboration.

The data transmission to the HMI can be done wirelessly. Depending on the operating concept, a central control unit can be replaced with a wireless hand-held device that can carry out the complete parameterization of the system. Further information about the process or the status of the system can be easily accessed or adapted via remote maintenance when linked up to the Internet.

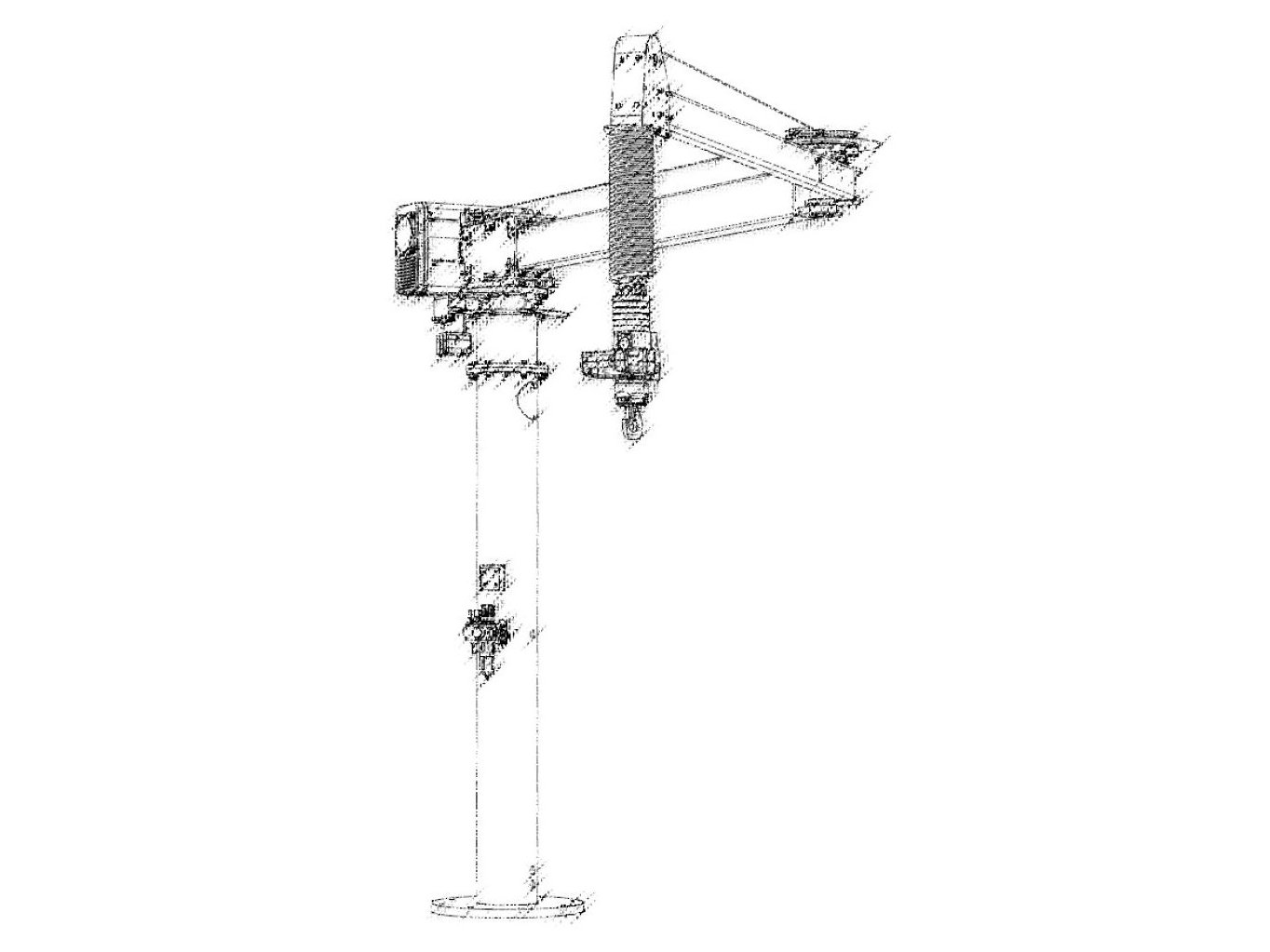

An ergonomic lifting aid for machine operators, our articulated arms are combined with rope balancers and can be anchored to pillars, columns…

A combination of pneumatic hoists with parallelograms, our parallelogram manipulator range is a gravity-defying solution that enables the equalization…

Capable of lifting loads of up to 1000 kg, our lifting axes are perfect for rigid and off-centered loading. It can also be combined with a chain hoist.