Product configurator

Healthy, motivated, capable employees are crucial to success and deserve protection and support. Back and musculoskeletal ailments do considerable damage to business and the economy. They are the most common reason for sick leave and reduced performance at the workplace. A large number of these illnesses can be attributed to handling loads incorrectly. Production processes and services are therefore delayed or cannot be completed.

Employees whose work causes improper load handling must be protected and supported by suitable equipment, according to the EU Framework Directive. The key indicator method allows practical analysis and assessment of objectively present work stresses without special ergonomic knowledge or time-consuming calculations. It lets you evaluate your workplace on your own and detect possible impairments.

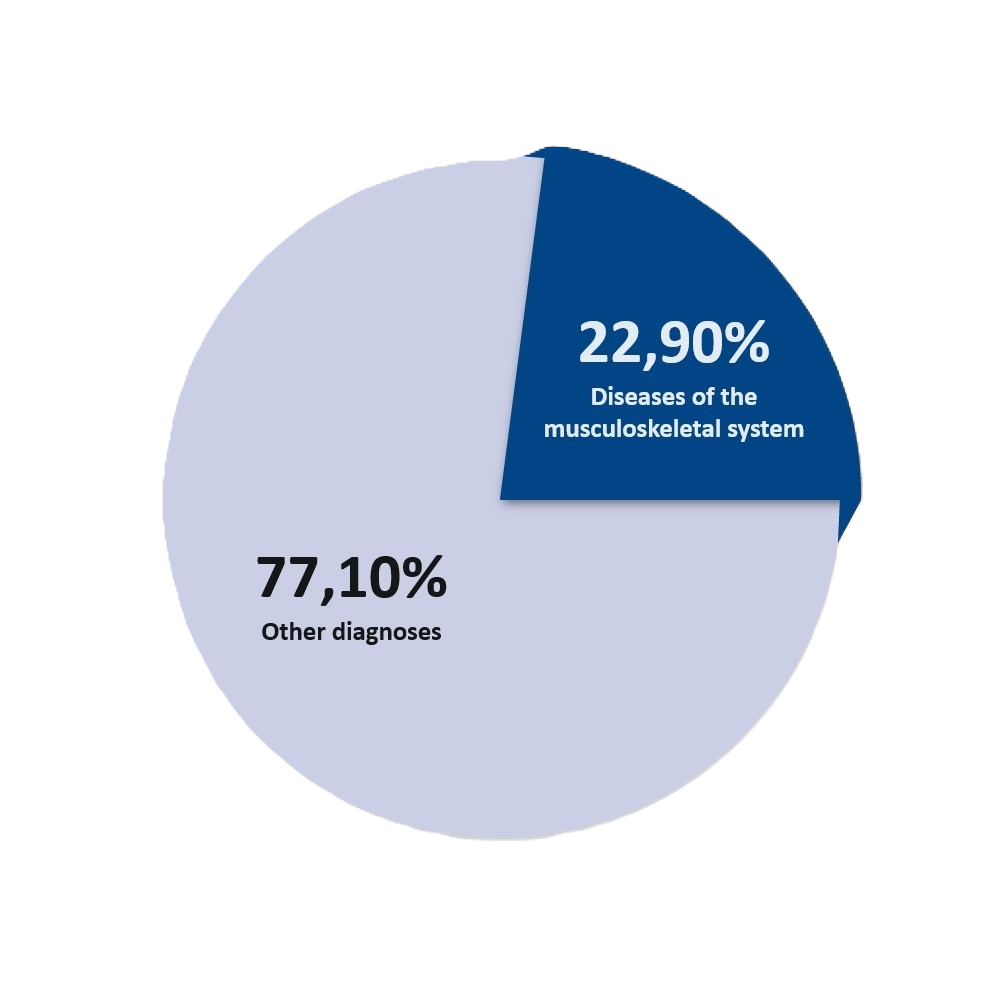

Musculoskeletal diseases are among the most common diseases according to the analyzes of all major health insurance companies. According to the Federal Statistical Office, the medical costs caused by these diseases come fourth: They amounted to 34.2 billion euros in 2015 (source: bundestag.de).

In 2016, according to the health insurance AOK, more than a fifth of all days of incapacity to work caused by an illness are due to a musculoskeletal illness (22.9%).

According to the EU Framework Directive, a worker should lift no more than 10 kg and is not allowed to lift more than 15 kg. For this reason, equipment support is crucially important in the logistics industry.

Ergonomic material handling allows each employee to be assigned demanding logistics tasks with uniformly high availability and low error rates.

An ergonomically designed workplace ensures:

As from now 90 years, ZASCHE has developed sophisticated technologies for moving goods, bringing the logistics industry ever more to the fore. Ergonomics have become more and more important for fast, easy movement of goods. With ZASCHE, you have a reliable partner at your side.

We compensate for the growing load on your employees through ergonomic, technically sophisticated devices that gain worker acceptance. Sequencing and commissioning requires intuitive load handling, and the lifting equipment should never impair the worker.

During the developing of our manipulators, hoists and crane systems, we always keep the health and safety of the employees in mind.

This applies to our standard products as well as to semi-automatic handling devices, individual productions for your special requirements and special devices.

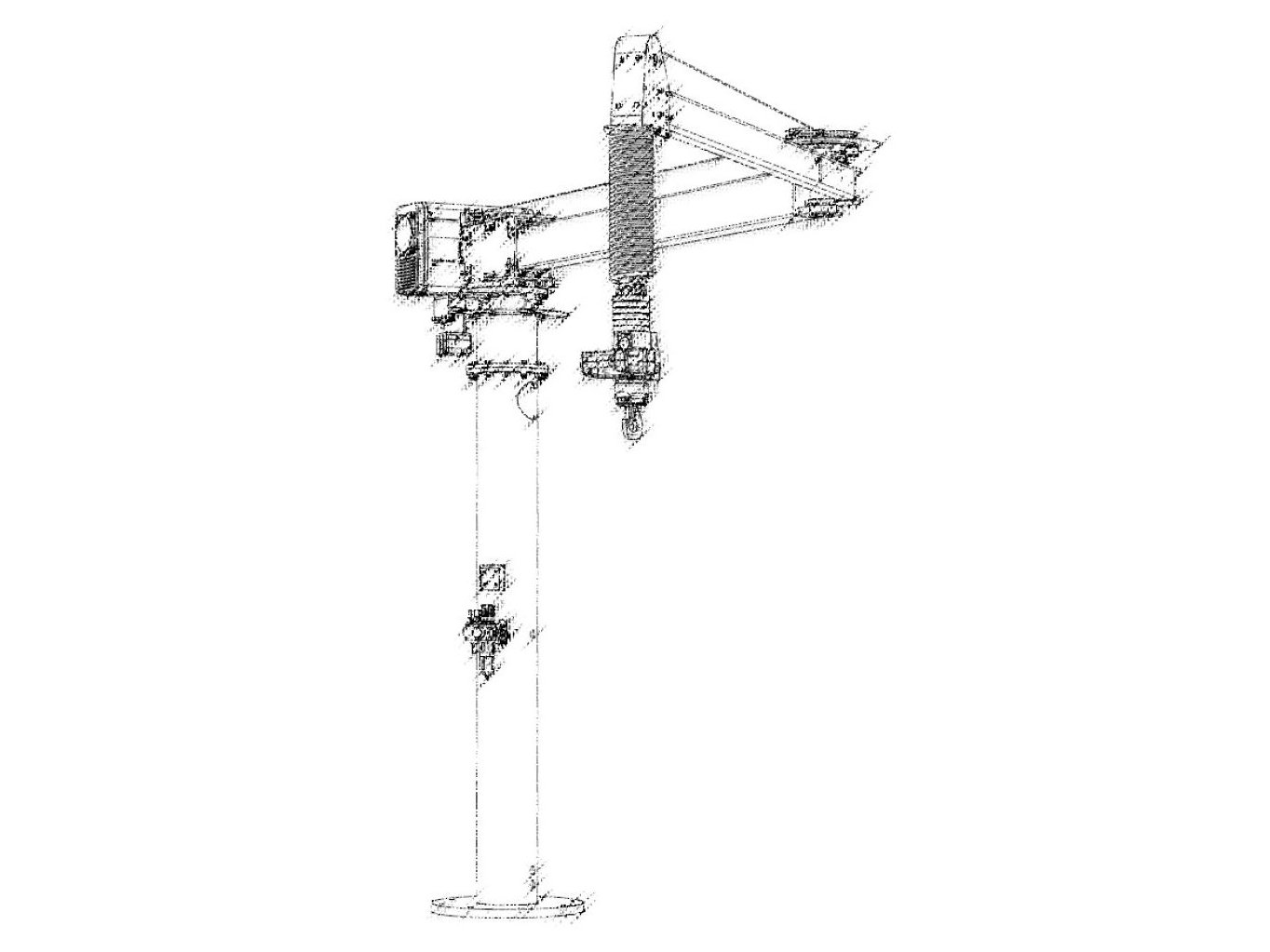

An ergonomic lifting aid for machine operators, our articulated arms are combined with rope balancers and can be anchored to pillars, columns…

A combination of pneumatic hoists with parallelograms, our parallelogram manipulator range is a gravity-defying solution that enables the equalization…

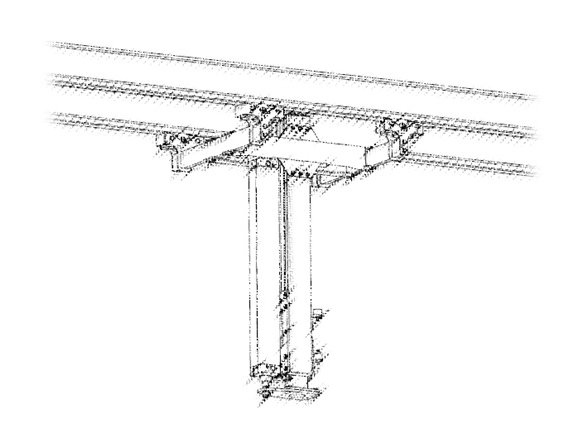

Capable of lifting loads of up to 1000 kg, our lifting axes are perfect for rigid and off-centered loading. It can also be combined with a chain hoist.